Infrastructure

| Sr.No. | Machine Name | Numbers | Image |

|---|---|---|---|

| 01 |

CNC MACHINES A)Turning Centres B)Vertical Milling Centres |

12 3 |

|

| 02 |

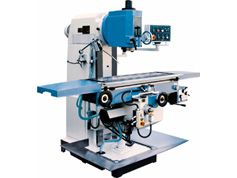

CONVENTIONAL MACHINES A) Lathe Machine B) Shapping Machine C) Cutting Machine D) Drilling Machine E) Radial Drilling Machine F) Milling Machine G) Surface Grinding Machine H) Thread Rolling Machine |

40 16 5 15 1 1 1 1 |

|

| 03 |

STAMPING MACHINES A) Laser Marking Machine B) Dot Matrix Machine |

1 2 |

|

| 04 |

QUALITY INSPECTION A) Helium Leak Testing Machine B) Universal Testing Machine C) Ultra Sonic Testing Machine D) Spectro Machine E) Type Test Machine F) Thread Profile Projector G) Hardness Testing Machine H) Sand Blasting Machine |

1 1 1 1 3 2 1 1 |

|

Quality Assurance

Inspection and Testing

All Suraj Enterprise Products are tested in accordance to internationally recognized standards or our own more stringent internal test procedures, which is developed considering the harsh field conditions. In addition to this we also offer specific testing to our client's requirement.

Raw Material Testing

All the material used for Manufacturing Suraj Instrument fittings and Instrument valves is tested for chemical & mechanical properties. The Results are confirmed to meet original material requirement before processing.

Material Traceability

All the material used for Manufacturing Suraj Instrument fittings and Instrument valvesis identified & fully traceable from raw material stage to final product.

Dimensional Inspection

Suraj Instrument fittings and Instrument valvesare checked for dimensional accuracy from raw material stage to in process & final product delivery by using calibrated measuring instruments.

In House Testing Option-Hydro Test Up To 60000 PSI

Suraj Instrument fittings and Instrument valvesare tested at a specified static pressure for a predetermined period for no leakage.

Pneumatic/Gas Test

Suraj Instrument fittings and Instrument valvesare subjected to Pneumatic test at 150psi air pressure and 2000psi Nitrogen pressure. Pneumatic/Gas test is carried out after hydro testing and complete drying of the items following Hydro-Test.

Helium gas test can be offered on request.

Pressure Cycle Test

Suraj Instrument fittings and Instrument valvesare tested for pressure cycle test where pressure surges from Opsi to 5000psi. The test is conducted at the rate of 25 to 45 cycles per minute with the digital counter. Client can specify number of cycles and condition of test.

Vibration Test

Suraj Instrument fittings and Instrument valvesare tested for severe vibration under impulse pressure for no leakage

Temprature Test on Request

Suraj Instrument fittings and Instrument valvesare heated to temperature upto 350oC for one complete cycle of 4 hours. After that valves are again subjected to Hydro, Pneumatic and Pressure cyclic test for no leakage. All the above test are certified by our own Quality control department and can be witnessed by client or third party inspection company of client's choice.